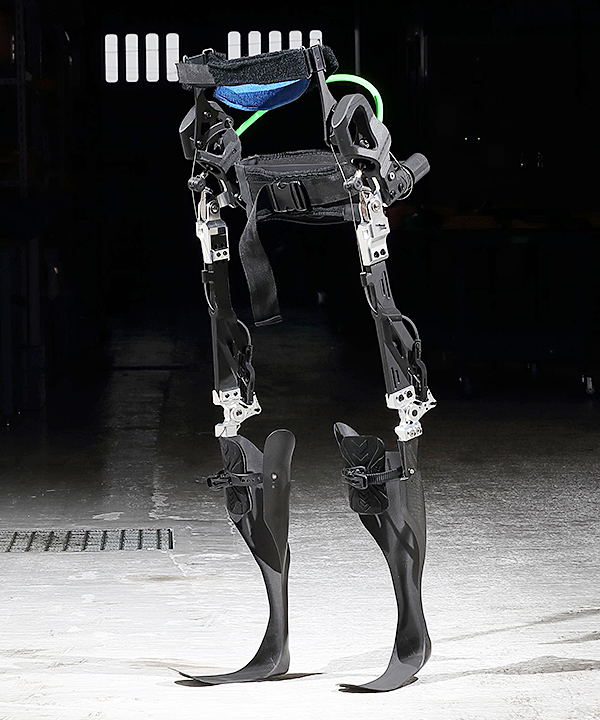

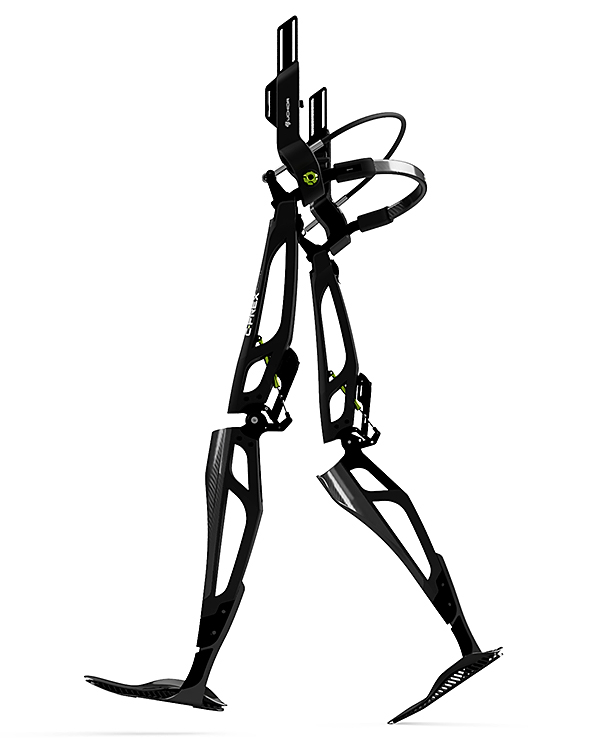

C-FREX

– CFRP製二足歩行アシスト装具 –

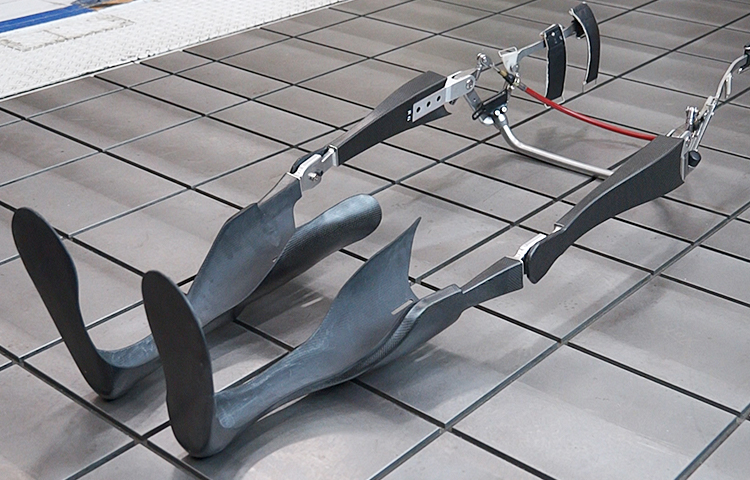

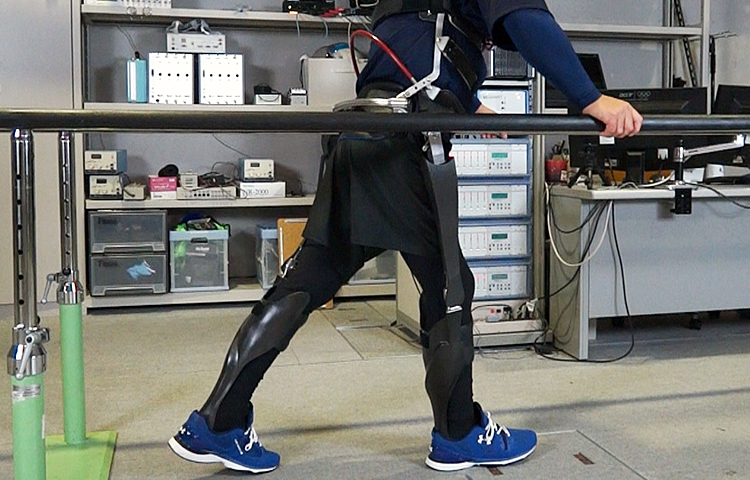

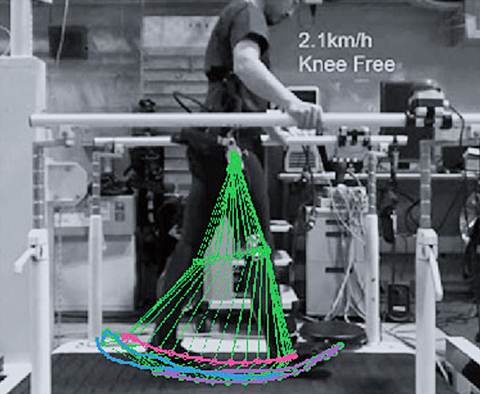

C-FREX(シーフレックス)は、脊髄損傷者が身体機能を維持するために使用するCFRP製歩行装具です。

外部動力を用いずに脊髄損傷者が健常者に近い動作での歩行を実現するため、まったく新しい装具を開発しています。

C-FREX開発コンセプト

共同開発者

国立障害者リハビリテーションセンター研究所

神経筋機能系障害研究室室長 河島則天

JEC World 2016 受賞

N1モデルは、2016年3月、フランス・パリで開催された複合材料業界の世界最大見本市JEC(Journals and Exhibitions on Composites)にてINNOVATION AWARDを受賞しました。車いすとの一体型モビリティデバイスは、世界でも類を見ない革新的な発明品であるとの評価を得たことが、受賞に結びつきました。

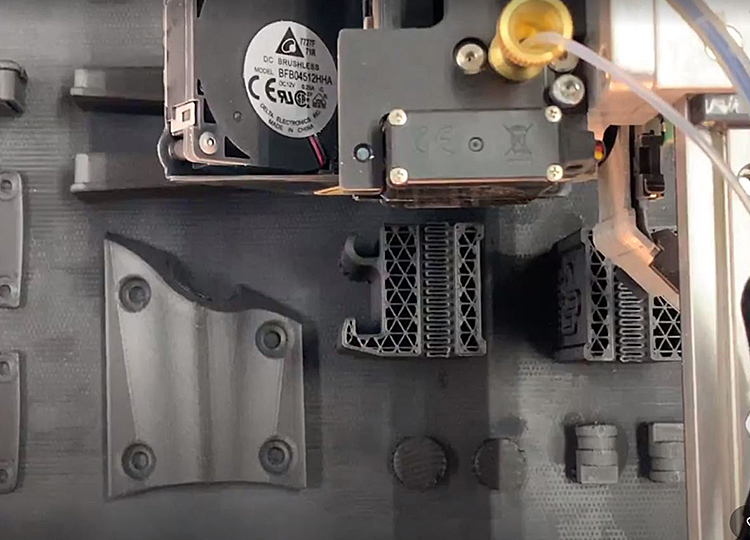

カーボン連続繊維入り3Dプリンタの導入

3Dプリンタは少量生産を得意とし、多様な形状・サイズにオーダーメードで対応可能です。中でも、より高強度な成形が可能なMark Forged社のカーボン連続繊維入り3Dプリンタの導入し、開発リードタイムの短縮を図るとともに、強度試験・評価を独自に実施しています。

REHACARE2019に出展

2019年9月18日から21日までドイツ・ドュッセルドルフで開催された福祉・介護機材展REHACARE2019に初出展しました。会場では障害当事者から医療・福祉・介護業界の方々まで約5万人が訪れました。車椅子ユーザーや各国の販売代理店より多くの反響を頂きました。

CES2020に出展

2020年1月7日から10日まで米国ラスベガスで開催される家電見本市イベント CES2020 にC-FREX(N2モデル)を初出展しました。会場には約20万人の来場者が訪れ、脊髄損傷者による歩行デモを行いました。現地の記者や研究機関の方からも、多くの反響を頂きました。

髙橋和廣さんがトーチに聖火を灯す

2021年7月14日、パラアイスホッケー日本代表として活躍した開発当初からのパートナーである髙橋和廣さん(カズさん)が装着して聖火リレーを実現しました。新型コロナウイルスの感染拡大の影響で公道での実施が中止された都内の聖火リレーはトーチに聖火を灯すセレモニーとなりましたが、改良を重ねた最新のC-FREXで歩くカズさんはとても凛々しく、関係者の見守る中を一歩一歩力強く歩く姿を見せてくれました。