What is CFRP?

CFRPとは?

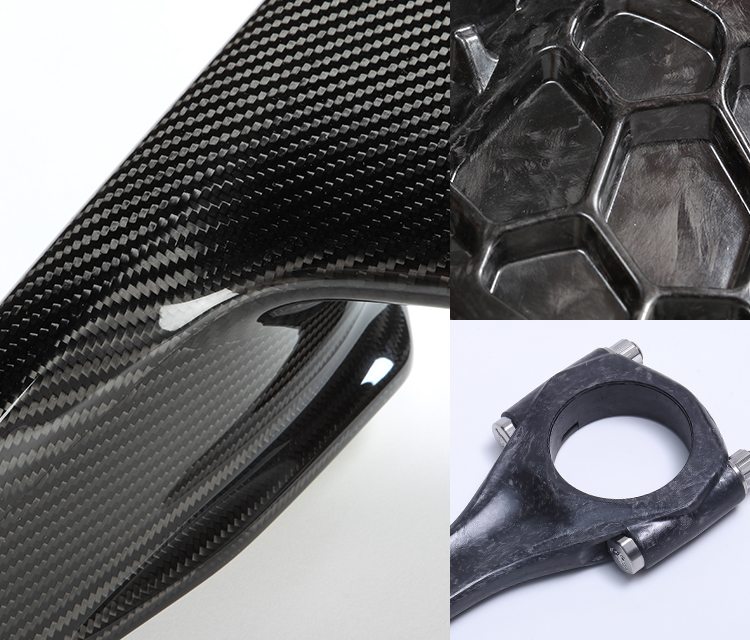

CFRP(Carbon Fiber Reinforced Plastics)とは、炭素繊維と樹脂との複合材料で炭素繊維強化プラスチックの意味です。

特徴として、鉄やアルミなどの金属材料よりも低密度でありながら、力学特性に優れた比強度が高い、軽くて強い材料です。

また、設計要領にも特徴をもち繊維方向に弾性率及び強度が高く、配置した繊維方向の割合を変えることで自由な設計ができることから、金属のような等方材料とは全く違った異方性を有する設計が可能となるのです。

資料提供:東レ株式会社

航空宇宙分野

ロケット / 人工衛星 / 軍用機 / 民間旅客機 / ヘリコプターブレード等

二輪・自動車分野

レーシングカー / バイク(F1 / GT / MotoGP等) / 高級スポーツカー / 競技用自転車等

医療分野

レントゲンやX線CTの天板 / 車いす / 人工骨等

鉄道分野

鉄道車両 / 新幹線(700系先頭部分)等

工業(ロボット)分野

測定機器 / 搬送用ロボットアーム / ノートパソコン等

建築・土木分野

橋脚など鉄筋に変わる腐食劣化の少ない補強材等

エネルギー分野

大型風力発電のブレードの桁 / 送電線の芯材等

スポーツ・レジャー分野

ゴルフシャフト / テニスラケット / 釣り竿 / 自転車等

海洋分野

深海探査船 / レース舟艇等